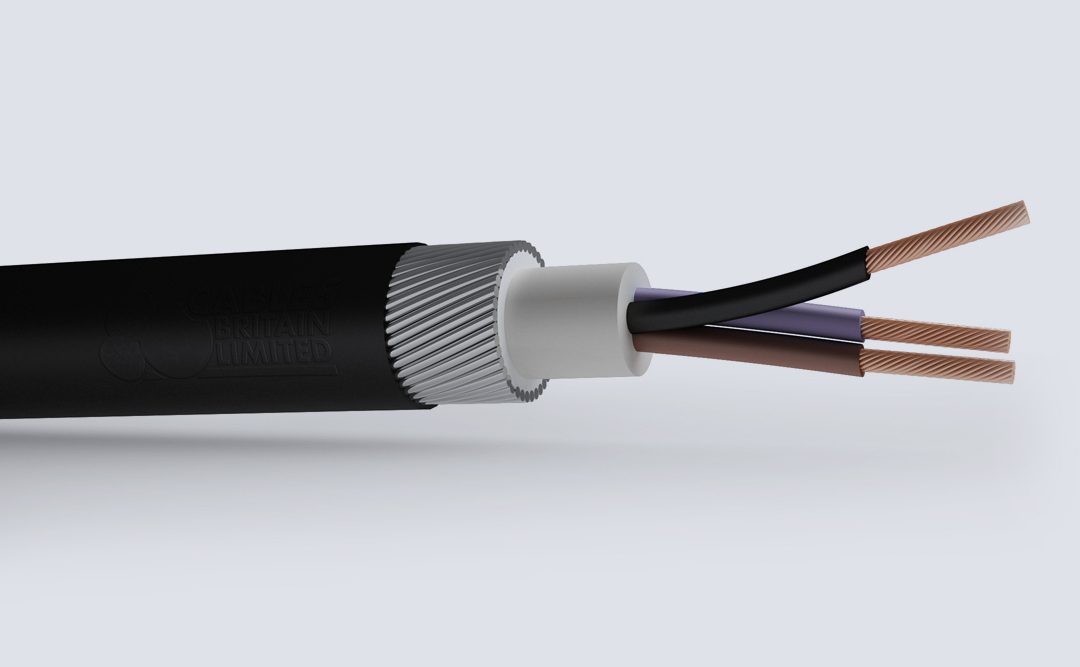

Cable construction

| Conductor | Class 2 stranded copper conductor according to BS EN 60228 |

| Insulation | XLPE (Cross-Linked Polyethylene) |

| Bedding | PVC (Polyvinyl Chloride) |

| Armour | SWA (Steel Wire Armour) |

| Sheath | PVC (Polyvinyl Chloride) |

Dimensions - BS5467 XLPE/PVC/AWA/PVC (Copper)

| No. of Cores | Nominal Cross Sectional Area mm² | Nominal Thickness of Insulation mm | Nominal Overall Diameter mm | Nominal Weight kg/km | BW / CW Gland | Wraparound Cleats | |

|---|---|---|---|---|---|---|---|

| Under Armour | Overall | ||||||

| 2 | 1.5 | 0.6 | 7.3 | 12.1 | 302 | 20 | CC5 |

| 2 | 2.5 | 0.7 | 8.5 | 13.6 | 346 | 20 | CC6 |

| 2 | 4 | 0.7 | 9.4 | 14.7 | 410 | 20S | CC7 |

| 2 | 6 | 0.7 | 10.5 | 15.9 | 499 | 20 | CC7 |

| 2 | 10 | 0.7 | 12.3 | 18 | 648 | 20 | CC8 |

| 2 | 16 | 0.7 | 14.3 | 20.4 | 978 | 20 | CC9 |

| 2 | 25 | 0.9 | 14.7 | 20.4 | 1290 | 25 | CC9 |

| 2 | 35 | 0.9 | 16.8 | 23.3 | 1500 | 25 | CC10 |

| 2 | 50 | 1 | 19 | 25.8 | 1890 | 25 | CC11 |

| 2 | 70 | 1.1 | 22 | 29 | 2450 | 32 | CC12 |

| 2 | 95 | 1.1 | 25.1 | 33.1 | 3300 | 32 | CC14 |

| 2 | 120 | 1.2 | 27.9 | 36.1 | 4020 | 40 | CC16 |

| 2 | 150 | 1.4 | 30.9 | 39.3 | 4750 | 40 | CC16 |

| 3 | 1,5 | 0.6 | 7.8 | 12.6 | 330 | 20 | CC5 |

| 3 | 2.5 | 0.7 | 9.2 | 14.1 | 390 | 20S | CC6 |

| 3 | 4 | 0.7 | 10 | 15.3 | 464 | 20S | CC7 |

| 3 | 6 | 0.7 | 11.2 | 16.6 | 568 | 20 | CC7 |

| 3 | 10 | 0.7 | 13.1 | 19.5 | 866 | 20 | CC8 |

| 3 | 16 | 0.7 | 15.3 | 21.6 | 1152 | 25 | CC9 |

| 3 | 25 | 0.9 | 18.9 | 23.6 | 1800 | 25 | CC11 |

| 3 | 35 | 0.9 | 21.3 | 25.7 | 2230 | 32 | CC12 |

| 3 | 50 | 1 | 21.7 | 28.5 | 2490 | 32 | CC12 |

| 3 | 70 | 1.1 | 25.2 | 32.2 | 3290 | 32 | CC14 |

| 3 | 95 | 1.1 | 28.8 | 37 | 4440 | 40 | CC16 |

| 3 | 120 | 1.2 | 32 | 40.4 | 5470 | 40 | CC16 |

| 3 | 150 | 1.4 | 35.9 | 45.5 | 6930 | 50S | CC18 |

| 3 | 185 | 1.6 | 40 | 49.8 | 8350 | 63S | CC20 |

| 3 | 240 | 1.7 | 44.9 | 55.1 | 10400 | 63S | - |

| 3 | 300 | 1.8 | 49.8 | 60.2 | 12600 | 63S | - |

| 3 | 400 | 2 | 55.8 | 66.6 | 14600 | 75S | - |

| 4 | 1.5 | 0.6 | 8.5 | 13.3 | 365 | 20S | CC6 |

| 4 | 2.5 | 0.7 | 9.9 | 15 | 438 | 20 | CC6 |

| 4 | 4 | 0.7 | 11 | 16.4 | 532 | 20 | CC7 |

| 4 | 6 | 0.7 | 12.3 | 18.7 | 764 | 20 | CC8 |

| 4 | 10 | 0.7 | 14.5 | 21.1 | 1013 | 25 | CC9 |

| 4 | 16 | 0.7 | 17 | 23.4 | 1360 | 25 | CC10 |

| 4 | 25 | 0.9 | 21 | 26.1 | 2160 | 32 | CC11 |

| 4 | 35 | 0.9 | 23.6 | 28.6 | 2690 | 32 | CC12 |

| 4 | 50 | 1 | 25 | 32 | 3130 | 32 | CC14 |

| 4 | 70 | 1.1 | 29.5 | 37.7 | 4500 | 40 | CC16 |

| 4 | 95 | 1.1 | 33.3 | 41.7 | 5600 | 50S | CC18 |

| 4 | 120 | 1.2 | 37.5 | 47.1 | 7400 | 50 | CC20 |

| 4 | 150 | 1.4 | 41.6 | 51.4 | 8780 | 50 | - |

| 4 | 185 | 1.6 | 46.4 | 56.6 | 10630 | 63S | - |

| 4 | 240 | 1.7 | 52.6 | 63 | 13390 | 63 | - |

| 4 | 300 | 1.8 | 58 | 68.8 | 16290 | 75S | - |

| 4 | 400 | 2 | 65.4 | 78.1 | 19800 | 90 | - |

| 5 | 1.5 | 0.6 | 9.7 | 14.3 | 410 | 20S | CC6 |

| 5 | 2.5 | 0.7 | 11.7 | 16.1 | 470 | 20 | CC7 |

| 5 | 4 | 0.7 | 13 | 17.8 | 710 | 20 | CC7 |

| 5 | 6 | 0.7 | 14.5 | 20 | 876 | 25 | CC8 |

| 5 | 10 | 0.7 | 17.2 | 22.9 | 1165 | 25 | CC10 |

| 5 | 16 | 0.7 | 20 | 26.6 | 1742 | 32 | CC11 |

| 5 | 25 | 0.9 | 24.7 | 31.5 | 2323 | 32 | CC14 |

| 5 | 35 | 0.9 | 27.8 | 34.8 | 2932 | 40 | CC14 |

| 5 | 50 | 1 | 32.4 | 40.4 | 4192 | 50S | CC16 |

| 7 | 1.5 | 0.6 | 10.2 | 15.2 | 470 | 20S | CC6 |

| 7 | 2.5 | 0.7 | 12.3 | 17.1 | 600 | 20 | CC7 |

| 7 | 4 | 0.7 | 13.6 | 19.1 | 881 | 20 | CC8 |

| 12 | 1.5 | 0.6 | 13.7 | 19.4 | 780 | 20 | CC8 |

| 12 | 2.5 | 0.7 | 16.3 | 22.4 | 1000 | 25 | CC9 |

| 19 | 1.5 | 0.6 | 16.2 | 22.2 | 1000 | 25 | CC9 |

| 19 | 2.5 | 0.7 | 19.9 | 26.6 | 1540 | 25 | CC11 |

| 27 | 1.5 | 0.6 | 20 | 26.7 | 1500 | 32 | CC11 |

| 27 | 2.5 | 0.7 | 24 | 30.7 | 1950 | 32 | CC14 |

| 37 | 1.5 | 0.6 | 22.3 | 29 | 1800 | 32 | CC12 |

| 37 | 2.5 | 0.7 | 26.9 | 33.8 | 2350 | 40 | CC14 |

Class 2 Stranded Conductors for Single Core and Multi-Core Cables

| Nominal Cross Sectional Area mm² | Minimum No. Of Wires In Conductor | Maximum Resistance of Conductor At 20ºC | |||||

|---|---|---|---|---|---|---|---|

| Circular | Circular Compacted | Shaped | Annealed Copper Conductor | ||||

| Cu | Al | Cu | Al | Cu | Al | Plain Wires ohms/km | |

| 1.5 | 7 | - | 6 | - | - | - | 12.1 |

| 2.5 | 7 | - | 6 | - | - | - | 7.41 |

| 4 | 7 | - | 6 | - | - | - | 4.61 |

| 6 | 7 | - | 6 | - | - | - | 3.08 |

| 10 | 7 | 7 | 6 | 6 | - | - | 1.83 |

| 16 | 7 | 7 | 6 | 6 | - | - | 1.15 |

| 25 | 7 | 7 | 6 | 6 | 6 | 6 | 0.727 |

| 35 | 7 | 7 | 6 | 6 | 6 | 6 | 0.524 |

| 50 | 19 | 19 | 6 | 6 | 6 | 6 | 0.387 |

| 70 | 19 | 19 | 12 | 12 | 12 | 12 | 0.268 |

| 95 | 19 | 19 | 15 | 15 | 15 | 15 | 0.193 |

| 120 | 37 | 37 | 18 | 15 | 18 | 15 | 0.153 |

| 150 | 37 | 37 | 18 | 15 | 18 | 15 | 0.124 |

| 185 | 37 | 37 | 30 | 30 | 30 | 30 | 0.0991 |

| 240 | 37 | 37 | 34 | 30 | 34 | 30 | 0.0754 |

| 300 | 61 | 61 | 34 | 30 | 34 | 30 | 0.0601 |

| 400 | 61 | 61 | 53 | 53 | 53 | 53 | 0.047 |

Current Carrying Capacity

| Nominal Cross Sectional Area mm² | Reference Method C (Clipped Direct) | Reference Method E (In Free Air or on a Perforated Cable Tray, Horizontal or Vertical) | Reference Method D (direct in ground or in ducting in ground, in or around Buildings) | |||

|---|---|---|---|---|---|---|

| 1 Two Core Cable Single-Phase AC or DC | 1 Three or 1 Four core cable Three-phase AC | 1 Two core cable Single-Phase AC or DC | 1 Three or 1 Four core cable Three-Phase AC | 1 Two core cable single-phase AC or DC | 1 Three or 1 Four core cable three-phase AC | |

| 1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

| 2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

| 4 | 49 | 42 | 52 | 44 | 43 | 36 |

| 6 | 62 | 53 | 66 | 56 | 53 | 44 |

| 10 | 85 | 73 | 90 | 78 | 71 | 58 |

| 16 | 110 | 94 | 115 | 99 | 91 | 75 |

| 25 | 146 | 124 | 152 | 131 | 116 | 96 |

| 35 | 180 | 154 | 188 | 162 | 139 | 115 |

| 50 | 219 | 187 | 228 | 197 | 164 | 135 |

| 70 | 279 | 238 | 291 | 251 | 203 | 167 |

| 95 | 338 | 289 | 354 | 304 | 239 | 197 |

| 120 | 392 | 335 | 410 | 353 | 271 | 223 |

| 150 | 451 | 386 | 472 | 406 | 306 | 251 |

| 185 | 515 | 441 | 539 | 463 | 343 | 281 |

| 240 | 607 | 520 | 636 | 546 | 395 | 324 |

| 300 | 698 | 599 | 732 | 628 | 446 | 365 |

| 400 | 787 | 673 | 847 | 728 | - | - |

Ambient temperature: 30ºC

Conductor operating temperature: 90ºC

Notes

1. Where a conductor operates at a temperature exceeding 70ºC it must be ascertained that the equipment connected to the conductor is suitable for the conductor operating

temperature (see Regulation 512.1.2 of the 17th Edition of IEE Wiring Regulations).

2. Where cables in this table are connected to equipment or accessories designed to operate at a temperature not exceeding 70ºC , the current ratings given in the equivalent

table for 70ºC thermoplastic insulated cables (Table 4D3A) must be used (see Regulation 523.1 of the 17th Edition of IEE Wiring Regulations).

The above table is in accordance with Table 4E3A of the 17th Edition of IEE Wiring Regulations.

Voltage Drop

| Nominal Cross Sectional Area mm² | Two Core Cable DC | Two Core Cable Single-Phase AC mV/A/m | Three Or Four Core Cable Three-Phase AC mV/A/m | ||||

|---|---|---|---|---|---|---|---|

| 1.5 | 31 | 31 | 27 | ||||

| 2.5 | 19 | 19 | 16 | ||||

| 4 | 12 | 12 | 10 | ||||

| 6 | 7.9 | 7.9 | 6.8 | ||||

| 10 | 4.7 | 4.7 | 4 | ||||

| 16 | 2.9 | 2.9 | 2.5 | ||||

| r | x | z | r | x | z | ||

| 25 | 1.85 | 1.85 | 0.160 | 1.900 | 1.600 | 0.140 | 1.650 |

| 35 | 1.35 | 1.35 | 0.155 | 1.350 | 1.150 | 0.135 | 1.150 |

| 50 | 0,98 | 0.99 | 0.155 | 1.000 | 0.860 | 0.135 | 0.870 |

| 70 | 0.67 | 0.67 | 0.150 | 0.690 | 0.590 | 0.130 | 0.600 |

| 95 | 0.49 | 0.50 | 0.150 | 0.520 | 0.430 | 0.130 | 0.450 |

| 120 | 0.39 | 0.40 | 0.145 | 0.420 | 0.340 | 0.130 | 0.370 |

| 150 | 0.31 | 0.32 | 0.145 | 0.350 | 0.280 | 0.125 | 0.300 |

| 185 | 0.25 | 0.26 | 0.145 | 0.290 | 0.220 | 0.125 | 0.260 |

| 240 | 0.195 | 0.20 | 0.140 | 0.240 | 0.175 | 0.125 | 0.120 |

| 300 | 0.115 | 0.16 | 0.140 | 0.210 | 0.140 | 0.120 | 0.185 |

| 400 | 0.12 | 0.13 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Conductor operating temperature: 90ºC

r = Resistive Component

x = Reactive Component

z = Impedance Value

For cables having conductors of 16mm2 or less cross sectional area their inductances can be ignored and (mV/A/m)r values only are tabulated. For cables having conductors greater than 16mm2, cross sectional area the impedance values are given as (mV/A/m)z, together with the resistive component (mV/A/m)r and the reactive component (mV/A/m)x.

The above paragraph is extracted from Appendix 4 of the 17th Edition of IEE Wiring Regulations.

.

Our power cables have many accessories.

For more information, don’t hesitate to call us on 0121 508 6890 or get in touch via our Contact Page.

BS 5467 SWA PVC 0.6/1kV Cable BS 6724 SWA LSZH 0.6/1kV CableBS 5467 SWA PVC 0.6/1kV Cable

BS 6724 SWA LSZH 0.6/1kV Cable